We’re nearly one month into 2018, and I’m wondering just how many people have already given up on their resolutions? How long did you last? One day? One week? You’re not alone! We have many pain points in the fiber optic industry, just like we have in our own lives, that we can never quite seem to overcome. We often make (and break) promises about the same things: weight loss can be likened to streamlining bulky and slow processes with automation, being on time can be related to becoming more reliable and consistent, and getting a grip on finances is similar to controlling increasing labor costs.

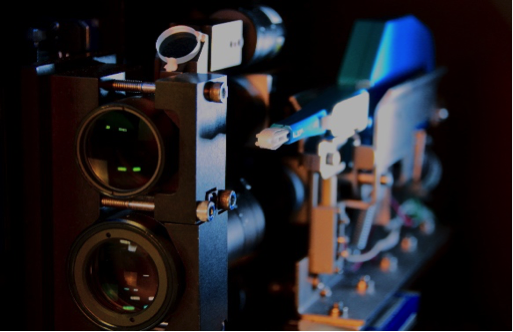

The fiber optic industry spent years in the dark ages of manual inspection. Slowly but surely, companies are switching over to automated systems. Automation is clearly the way of the future, and every new system on the market attempts to tackle the issues we face in both high and low throughput environments. Most fiber scopes, however, fall short of the mark. While everyone has focused solely on the inspection side of the fiber optic connector quality control process, they have forgotten about cleaning. Has anyone truly automated their process if technicians still have to actively remove, clean, and re-insert each part over and over again? The answer is simply…no. This outdated process has an enormous impact on supply chain partners with high throughput needs, and desperately needs to be streamlined. FiberQA has gone the distance by combining both inspection and cleaning into a single, autonomous system: the AVIT™. Integrated right inside of each AVIT system (a total of 5 different models) is a disposable FastCLEAN cartridge controlled by internal robotics and automated software.

The fiber optic industry spent years in the dark ages of manual inspection. Slowly but surely, companies are switching over to automated systems. Automation is clearly the way of the future, and every new system on the market attempts to tackle the issues we face in both high and low throughput environments. Most fiber scopes, however, fall short of the mark. While everyone has focused solely on the inspection side of the fiber optic connector quality control process, they have forgotten about cleaning. Has anyone truly automated their process if technicians still have to actively remove, clean, and re-insert each part over and over again? The answer is simply…no. This outdated process has an enormous impact on supply chain partners with high throughput needs, and desperately needs to be streamlined. FiberQA has gone the distance by combining both inspection and cleaning into a single, autonomous system: the AVIT™. Integrated right inside of each AVIT system (a total of 5 different models) is a disposable FastCLEAN cartridge controlled by internal robotics and automated software.

With automation comes a high level of consistency and reliability that simply cannot be achieved by an ever-changing cast of technicians. AVIT’s robotics precisely control the positioning and pressure of the FastCLEAN tip like no human can, eliminating cleaner-to-part alignment errors that occur frequently with technician-operated manual cleaners. Automating this process removes operator error that can lead to unnecessary re-contamination and costly part damage. AVIT systems only require a technician to plug in the parts and initiate the test, freeing them to complete other tasks while the entire inspect/clean cycle(s) is completed independently. There is no other system available on the market like it.

While manual inspection scopes and handheld cleaners can be inexpensive on the front end, they can cost you dearly in the long run. The implementation of automated cleaning addresses the uncontrolled, runaway consumable costs many supply chains face. Manual cleaners pose a high risk for re-contamination and part damage from clumsy, excessive handling, while the automated FastCLEAN built-in to each AVIT system dramatically reduces those risks.

Facing our New Year’s resolutions can be a daunting task, but with fully automated systems like the AVIT, it doesn’t have to be! The addition of automated cleaning will streamline your process with reliable, precision robotics, and significantly reduce the inflated consumable and labor costs associated with manual cleaners. What are your Quality Control Resolutions for 2018? Comment below!

Events in 2018:

OFC Booth #2422 13-15 March 2018 (San Diego, California)

ECOC Booth #269 24-26 Sept 2018 (Rome, Italy)

AVFOP Table #TBD 13-15 Nov 2018 (Portland, Oregon)

Like, follow, subscribe and share with us online:

Twitter / @FiberQA

LinkedIn / @FiberQA

Facebook / @FiberQALLC

YouTube / @FiberQALLC